How to Swap an LS1 into a 240SX Part 1

Filed Under (Engine, LS1) by Michael Pica on 10-11-2010

Tagged Under : guide, LS1, S12, S13, s14, S15, small block 240SX, swap, tutorial, twistedsymphony

This write up will cover all the important topics on selecting the right parts to swap an LS1 into your 240SX. This Guide is written from the perspective of starting with a completely stock 240sx and swapping in a mostly stock LS1 style motor and can be applied to pretty much any S-Chassis from an S12 up through an S15, and any Gen III or Gen IV GM small block V8.

Part 1 covers the following topics: Choosing a Motor, Chassis Modification and Preparation, Engine Preparation.

Disclaimer: It should go without saying but the information here is for educational purposes only. I explain things to the best of my knowledge but I in no way shape or form guarantee this information, nor do I take responsibility for anything you do as a result of reading this.

What is an LS1?

In general this applies to ANY Generation III or Generation IV GM small block V8. While many of these motors have unique model numbers I’ll stick to using “LS1” just for simplicity, but what is written here also applies to the L33, L59, L76, L92, LC9, LFA, LH6, LH8, LM4, LM7, LMG, LR4, LS1, LS2, LS3, LS6, LS7, LS9, LSA, LSX, LQ4, LQ9, LY2, LY5, and the LY6 among others.

Chevy first sold their Gen III small block, titled the “LS1” exclusively in the Corvette in 1997, in 1998 it became an option for the F-body cars (Camaro and Firebird). These were all-aluminum 5.7L V8 motors making 305-350 hp and 300-365 ft-lb of torque. A few years later other variations started appearing such as the 4.8L iron block “LR4” all the way up through the 7.oL all-aluminum “LS7”.

Why use a GM LS-Series V8?

There are lots of benefits to choosing this motor as a power-plant for your car. Here is a short list of things to consider.

- Makes 280-500hp and 280-500ft-lbs of torque IN STOCK FORM. Yes, you can modify your I4 or V6 to make that kind of power, but consider that 280-500 is the STARTING point, with total OEM reliability. Any modifications push the power further up from there.

- Incredibly light weight for what they are. GM Quotes the weight of a fully dressed LS1 including, headers and all accessories at just under 450lbs. By comparison a similarly dressed KA24DE weighs 370lbs [source], and a similarly dressed RB series motor weighs over 560lbs.

- One of the most compact V8s. The LS-Series motors are push-rod style motors, this means that it has a single cam that sits in the valley between the heads (as opposed to Overhead Cam that sits on top of the heads). Because of this the motor has a very low center of gravity, and it fits comfortably in the relatively narrow S-Chassis engine bay.

- Amazing power potential. The LS-Series motors respond exceptionally well to modification. A simple cam swap can net up to 60whp depending on the motor and cams used. There are LS series motors making upward of 600whp without forced induction, and turbo and supercharged motors making hp numbers well into the 4 digit range.

- Exceptional aftermarket and OEM support. Since use of the LS-series motor is so wide spread there are lots of different OEM parts that can be bought used to serve as an upgrade, Similarly there are thousands of companies who make performance parts for these motors. Both the OEM and aftermarket support for the LS1 dwarfs what’s available for typical Nissan power plants.

- The OEM computer works like a Stand-Alone. It’s fairly rare that anyone running an LS1 would use a piggy-back or aftermarket engine computer, the factory computer is easily programmable and supports nearly as many tuning options as most aftermarket units for other motors. For around $500 you have a choice of several software suites and programming cables that will let you tune and adjust every aspect of the factory computer. To further this a lot more dyno shops are equipped to tune LS-series motors, and there are literally hundreds of shops that offer mail-in-tunes.

- Easy to source. Unlike JDM motors that require finding an importer and raising concerns over the vehicles history, LS-series motors can be found at nearly any salvage yard in the US, and in most cases you can find them still sitting in their original car, run a VIN history report, and the yard is much more likely to warranty and stand-behind the product beyond start-up.

- LEGAL. Unlike imported SRs or RBs LS-series motors are emissions legal in the US, they will pass OBDII, sniffer, visual and even CARB inspection as long as you use the proper equipment. There’s no trickery here, it is ACTUALLY legal.

- Reasonably Priced. A lot of people assume this is a super expensive swap, the truth is the price of this swap isn’t cut and dry. If you’re able to do some simple welding yourself, use a cheaper iron block motor, shop around and buy smart. This swap can easily be done for about the same price as a base level SR20DET swap. If buying smart, wrenching yourself but using a pre-made swap kit, with a 5.7L or 6.0L you can get it done for $6-$8K. Add in what it costs to bring an SR20DET up to the 350-400hp level and suddenly the price of an LS1 swap isn’t so bad.

Choosing a Motor Set:

All of the Gen III and Gen IV GM small block have identical exterior characteristics for the block and head, this means it doesn’t matter which one you use they will all mount up the same way, and external equipment is interchangeable and will all bolt up the same way.

Price and Power Differences:

The GM LS-series motors have a wide variety of options available in terms of price.

Cheapest option: In general the cheapest engines are the 4.8L and 5.3L iron block Truck variations. These are easily the most commonly available motors and also the cheapest, with complete motor-sets selling anywhere from $400-$800. Keep in mind that most of these motors will have clearance issues with accessories, intake and throttle body, so a new intake setup and accessory brackets will need to be purchased. Also it is exceedingly rare that you would find one of these motors with an appropriate transmission. The weight trade-off is not that bad as the Iron block adds an additional 80lbs of weight over similar all-aluminum variations. The factory spec power is usually around 280bhp and 300bhp respectively, and easily increased with a simple cam and intake swap. The iron block variations are better suited for turbo or super-charger setups.

Easiest Option: Arguably the easiest swap option is a motor and transmission set pulled out of an F-body or GTO, these will require the least amount of modification to work, the F-body motor will only need it’s oil pan swapped. The GTO motor will need the shifter on the trans mission swapped, though it also uses a Drive By Wire throttle so the gas pedal will need to be replaced as well (or the throttle body converted to cable). Corvette motors are the next easiest they only require an oil pan swap, and a Gas pedal swap (or throttle body conversion), however corvette transmission are not compatible with this swap so if using a Corvette motor you will need to source a transmission from an F-body or GTO.

Most Powerful Option: This is somewhat of an unanswerable question, The most powerful OEM setup is likely the 7.0L LS7 or Supercharged 6.2L LS9 which make over 500 and over 600hp in stock trim respectively. However even the cheaper variation can blow those numbers away with some modification. On top of that there are dozens of performance companies who sell brand new pre-built LS motors making hp figures in the 4 digit range. Expect to pay a handsome sum for any of these, anywhere from 5K to 20K or even higher, however if money is no object then the options are practically limitless.

The “Best” Option: This is my personal opinion, but I think the best middle of the road option between the dirt cheap iron block truck motors, and the super-powerful race ready motors is an all-aluminum 5.7 or 6.0L. The 5.7L are off course the LS1 and LS6 motors, found in the F-bodys, Corvettes, CTS-Vs, and first year GTOs, these regularly fetch $2000-$3000 for a used complete motor-set, the swap is easiest with these motors, they offer the best weight and really good stock performance. If you’re willing to spend about $1000 more you can pick up an all-aluminum 6.0L LS2, found in the later year GTOs, Corvettes, SSRs, CTS-Vs and the Trailblazer SS, as well as the L76 which is an all-aluminum 6.0L found in newer trucks, SUVs and the Pontiac G8. In stock trim these motors are rated anywhere from 350bhp and 365ft-lb for the 5.7L LS1 to 390bhp and 400ft-lb for certain variations of the LS2.

Fitment Concerns:

Accessories: The only accessory confirmed to work are those from the F-body cars, Corvettes, or GTOs. Accessories from truck motors and other vehicles will not fit.

Intake Plenum/Throttle Body: The intake plenum and throttle body from truck motors and some other vehicles will not work either, as they sit too tall and will hit the hood. Again the F-body, Corvette, and GTO motors are known to fit without issue.

Oil Pan: The only OEM oil pan that is known to fit is the GTO oil pan. Even with this pan you will still need to cut a notch in the engine cross member for fitment around the pan. Several kits offer custom oil-pans designed for this swap that fit without issue.

Exhaust Manifolds: The only OEM headers that are known to fit are Corvette Headers. C5 Corvette headers will need to be modified on the driver’s side to clear the steering column. C6 Z06 Corvette headers uses a non-standard oval outlet so you will need a matching flange to build your exhaust from, C6 LS2 (non Z06) headers are considered the most desirable as they can be used without modification. Several kits offer custom long-tube headers designed for this swap that fit without issue.

Chassis Modifications: The only Modification necessary to the chassis is that the Transmission tunnel must be hammered out for additional bell-housing clearance.

Sway Bar: Depending on the oil pan used the front OEM sway bar may not clear the front of the pan. This is problematic with the GTO pan and some custom swap-kit pans. In general there are three options. Purchase a larger sway bar that clears, purchase spacer that modify the mounting location of the sway bar, or modify the sway bar (or pan, or both) to fit.

Transmission Options:

Tremek T-56 (6-Speed Manual): Used in a number of vehicles from Corvettes, to Vipers, to Austin Martins. The only T-56 variations that will work with an LS1 are those found in a 1998 or newer f-body or an 2004 or newer GTO. T-56s found in SSR or Cadillac CTS may work with additional modification, but not much is known. The GTO T-56 requires that the shifter and a small part on the linkage be swapped out in order to fit properly. The F-body variations do not need this modification. GTO T-56s have a more aggressive gearing than the F-body T-56s and are generally more desirable. These transmissions fetch $2500 new and can generally be found used for $800-$1500.

Tremek T-6060 (6-Speed Manual): This is a beefed up version of the T-56 found in newer GM vehicles. It is found in the Pontiac G8 GXP, the newer Cadillac CTSs and the 2010+ Camaro V8. It has been suggested that these will bolt up and work, however not much information is known. Do to the newness and rarity of this transmission it’s highly recommended you do more research before swapping. These transmissions fetch $4000 new and there isn’t much of a used market yet.

This Chart show the gearing of the various compatible manual transmissions in comparison to the original 240sx gearing.

Other Manuals: No other manual transmission will bolt up to a T-56 without changing out the bell-housing, or input shaft, or both. In general the cost of modifying an alternative manual transmission is more than the cost of a T-56, and is generally not worth it.

GM 4L60-E (4-Speed Automatic): This is the Automatic that is most commonly found mated to LS1s on F-bodys and GTOs. Additional modification to the transmission tunnel is needed in that the forward transmission cross member mount holes have clearance issues. Also some of the custom swap-specific long-tube headers have clearance issues with the transmission pan.

Other Automatics: There are several other models of automatic transmissions that will bolt up to an LS1 without issue, however in general they have more clearance issues on top of the issues stated above concerning the 4L60-E. If there is a particular automatic transmission you are planning on using for the swap it is recommended you do further research into the specific clearance issues of that model.

Auto vs Manual Conversion:

I’ve seen some people question how difficult it is to swap from a motor set with an automatic transmission over to a motor set with a manual.

Mechanically everything bolts right up, you will need to swap to the proper flywheel but that’s about it. There is no difference in the computer between one transmission type and the other.

You should get the computer reprogrammed for the correct transmission but it shouldn’t prevent you from using it (it will just throw codes).

The only real difference is the wiring, some minor modifications will need to be made to the harness (removing the wires and connectors for one style transmission and replacing them with wires and connectors for the other style). In general the wiring conversion is a simple task with new connector pigtails easily sourced on the web. More details into the computer and wiring will be covered later.

The obvious benefit to buying a motor-set already mounted to the transmission you want is that you don’t have to source and install the transmission. I personally feel that buying a motor that was originally mounted to an automatic is generally the better option, even if you want a manual. The motor likely saw less stress since it’s impossible to shock the system with clutch drops and very hard to push it past red line, it’s much more likely that the car was owned by a “little old lady” driver as opposed to someone doing burnouts at stop lights. Also it forces you to install all new (or at least used and well inspected) clutch equipment. Considering the difficulty of removing the transmission once the motor is in the car, it’s highly advisable that you put in all brand new clutch parts just so you don’t have to worry about replacing it any time soon.

What Should Be Included:

If you’re buying a used motor-set to get your money’s worth you should make sure it includes everything you need. Having to buy a module here and a sensor there can add up unexpected costs fast. If a motor you’re considering is missing something, that’s ok, but you should know it before hand and value the price of the motor-set accordingly.

A number of these items aren’t typically included with a motor set, also some items might not be necessary if you’re not planning on adding that feature to your car (like AC or Cruise Control) but consider this a list of what you should grab if you have a whole car to grab parts from and you want a fully-featured swap:

- Accelerator Pedal (only for Drive by Wire cars)

- Accelerator Pedal Sub-Harness (only for Drive by Wire cars)

- Air Conditioning Belt Tension Pully(s) (only certain models have this)

- Air Conditioning Compressor and mount

- Air Conditioning Lines

- Air Conditioning Pressure Sensor

- Air Conditioning Sub-Harness or connectors

- Alternator and mount

- Alternator Sub-Harness or Connectors (especially if it’s a GTO motor)

- Brake Booster Vacuum Hose

- CAS (Crank Angle Sensor) (behind starter motor)

- Clutch and Pressure Plate (manual only, duh)

- Coil Packs (8 of them mounted on 2 metal frames each with its own sub-harness)

- Coolant Temp Sensor (front of driver’s side head)

- CPS (Cam Position Sensor) (behind intake plenum)

- Decorative Valve Covers (only certain models have these)

- Dip-Stick and Dip-Stick Tube

- Drive Belt Tension Pulley(s)

- EGR (Exhaust Gas Recirculation) Valve (only certain models have this)

- Engine Lift Brackets (only certain models have this)

- Exhaust Manifolds with heat Shields

- Flywheel (different for auto or manual)

- Flywheel Dust Covers (bolt to the back of the oil pan)

- Fuel Rails

- IAT (Intake Air Temp) Sensor (only certain models have this)

- Injectors

- Intake Plenum

- Knock Sensors (under intake plenum)

- MAF (Mas Air Flow) Sensor

- MAP (Mass Air Pressure) Sensor (on back of intake plenum)

- O2 sensors (there are 4 of them)

- Oil Fill Neck

- PCM (Powertrain control Module)

- PCV lines

- Power Steering Pump, reservoir, and mount

- Spark Plugs and wires

- Starter Motor

- Steam lines (bolted to top of block)

- TAC (Throttle Actuator Control) Module (only certain models have this)

- Throttle body

- Throttle Position Sensor

- Throwout Bearing (manual only)

- Uncut Wiring Harness

- Water Pump

What should be included with a T-56 (6-Speed Manual):

- Bellhousing

- Bellhousing Bolts

- CAGS (Computer aided Gear Selection) Solenoid

- Drive Shaft Yoke

- Reverse Lockout Solenoid

- Reverse Sensor

- Shift Knob

- Shifter

- Slave Cylinder

- Transmission Mount

- Vent Tube

- VSS (Vehicle Speed Sensor)

Chassis Modification:

This will cover the various things you should expect to do to your chassis before you can drop in your LS1.

Transmission Tunnel:

In general you will need to take a single-hand sledge and hammer out the area of the tunnel from the firewall back about 8 to 10 inches to the first pinch weld. The metal should be widened enough to add about 1 – 1.5 inches of additional clearance.

An S14 that has had it's transmission tunnel hammered out to clear an LS1.

Doing this does not compromise any equipment on the interior of the vehicle, nor does it compromise structural integrity of the chassis.

Engine Crossmember:

If using the GTO oil pan the engine crossmember will need to be notched along the front edge in order to clear the pan. After cutting to make additional clearance the void should be reinforced by welding on new metal plating.

An S14 Engine Crossmember that has been modified to clear a GTO oil pan.

In doing this you lose the torsional rigidity provided by the original box structure. It is recommended that very heavy gauge steel be used to reinforce the remaining center section, and the remainder of the sub-frame be stitch welded. If done properly this will make a sub-frame that is stronger than the original.

Again, this is only required if using the factory GTO oil pan as opposed to a swap-specific oil-pan

Sway Bars:

Most front sway bars will have fitment issues along the front of most LS1 oil pan options. There are a few options available to deal with this. These are listed in order of recommendation, with the most recommended option at the top.

More Accommodating Sway bars: Sikky makes both an S13 and S14 sway bar designed to fit around an LS1 oil pan, it offers a tremendous amount of space. It has also been confirmed that it clears a Nismo Power Brace.

LS1 S14 with Nismo Power Brace and Sikky Sway Bar.

It has been suggested that Certain R33 Skyline or A31 Cefiro front sway bars will fit and offer adequate clearance around an LS1 oil pan, however I recommend doing more research before purchasing. Some have claimed that certain aftermarket sway bars clear the oil pan as well, however there seems to be a lot of confusion surrounding this issue. The only bar confirmed to clear is the Sikky bar.

Spacers: Some swap-kit makers offer spacers, that lower and move further forward the front sway bar mounts in order to provide additional clearance along the front of the pan. In my experience these do provide additional clearance but the fitment of these is fairly poor and it makes it difficult to adjust and maintain other suspension components in this area, namely the tension rods.

Modifying the Sway Bar: It has been suggested that the OEM sway bar may be modified by placing it on a concrete surface and heating the vertical bends with a torch until it lays flat. It’s unclear exactly how much additional clearance this provides, it’s also unclear how this effects the performance of the sway bar.

Modifying the Oil Pan: Some have opted to notch the front of their LS1 oil pan to clear the sway bar, this works, however it is not recommended as it reduces the oil capacity of the pan and potentially compromises the oiling capabilities of the motor.

ABS Bracket and Lines:

If you’re keeping ABS as part of your conversion you will likely need to cut off the long arm of the bracket that holds up the ABS Actuator. The Actuator sits on a small platform and there is a long metal arm that goes from the platform all the way down to the frame rail where it is held on by a single bolt. This arm interferes with most exhaust manifold setups.

It is highly recommended that you remove your ABS actuator from the engine bay until the rest of the swap has been completed as it makes things a lot easier. There is no real loss removing this arm from the bracket as the remaining arm holds a majority of the actuator’s weight.

The brake lines going from the ABS Actuator to the passenger’s side front wheel, and from the ABS Actuator to the Rear Wheel junction block (located on the frame rail right at the firewall) will need to be modified for clearance. You will have noticed that they ran right along the bracket arm that needs to be removed. They should have enough length to be bent out of the way using a hard-line bending tool, however the best option is to simply get some new hard line and re-route them to run along the firewall and more toward the passenger’s side of the car.

Other Considerations:

Some other stuff you should consider doing to your chassis as part of this swap, but isn’t technically needed.

Additional Bracing:

Technically you don’t need to do anything to help strengthen the chassis, but I would recommend at least a Nismo Power brace (or similar) and front strut-tower brace to deal with the additional weight and fairly weak structured front end. Of course for high-horsepower (and in this case, high torque) applications a full cage is highly recommended as it is possible to twist up the whole car from the torque. The probably of this with a mostly stock swap is fairly low though

Rear Differential and Axles:

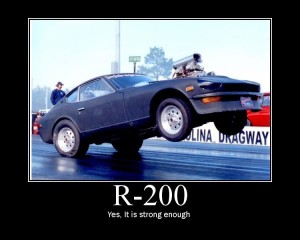

One of the first questions people ask me about this swap is “Is the R200/R200V rear end strong enough?”

Yes, it’s strong enough, I think that photo states the answer to that question well enough. From what I’ve heard from many with higher horsepower setups is that the weak point is the axles. Luckily there are several aftermarket “upgrade” options available as well as OEM direct replacements from Z-chassis and Infinitys that are stronger and can be swapped without much fuss. Unless you’re building a higher hp track car, you should be fine with the stock axles.

One thing you should consider though, is the final drive ratio. The GTO rear end has a 3.46:1 final drive and the F-body has a 3.27:1. By comparison the R200 in an S-chassis has a 4.083:1 final drive ratio. This is acceptable however you will probably be more comfortable with a lower ratio. There are several gear options available from various Infinitys and JDM spec S-chassis with lower ratios. The lowest I’ve seen is certain early 90s Infinity Q54s which were available with a 3.54:1 final drive ratio. The gears can be swapped out but the whole rear-diff can be bolted right up as well. If swapping the whole diff the output shafts are different which in turn requires you to swap out the rear axles and hubs from the 6-bolt pattern to the stronger 5-bolt pattern, so this is a good option anyway.

You should also consider having some form of LSD as opposed to just an open diff, you will need all the traction you can get with this motor. The factory VLSD or similar from an Infinity or Z is a definite upgrade from an open diff, however something such as a the S15 Silvia Helical LSD is your best OEM option. Beyond that there are drop-in Nismo, KAAZ and other LSD units you can use.

For more info on swapping the rear diff and axles it’s worth reading this guide: KA24DEvelopment – VLSD Swap Info

Wider Wheels and Tires:

Unlike a boosted motor making similar power the LS1 has gobs of low end torque, because of this anything beyond a slow and gentile squeeze of the accelerator will break loose the rear tires, even with an LSD. While technically not required it is highly recommended that you put the widest stickies tires you can fit on the back of the car. To put this into perspective the LS6 powered Z06 Corvette (which makes about 365bhp) uses 295-35R18 tires on 10.5″ wide wheels, and it can still break the rear end loose on a 3rd gear shift.

With the Right offset you should be able to run 9.5″ wide wheels with matching tires in the rear without any modification or crazy alignment. Beyond that a great site for seeing how different tire, wheel and offset configuration work on your car is RimTuck.com

Suspension:

The weight difference between the factory KA and an LS1 is negligible in terms of a street suspension. Though without putting some attention into the car’s handling you might as well just have saved yourself the trouble and bought a Camaro instead. While the LS1 swap does add a bit of weight, it has been shown that the LS holds it’s weight lower and further back, allowing it to maintain a 54/46 weight distribution (this has been proven more than once with swapped cars on corner weights) which is actually more balanced than the factory 56/44. This means that most off-the-shelf suspension setups should work well with this swap.

It’s also worth noting that Stance offers a variation of their GR+Pro series coilovers for both S13 and S14 designed specifically for an LS1 swap.

Another popular option among those who race their 240s in Time-Attack, Autocross and other motorsport are pieced together Koni or similar shocks with an adjustable Ground Control spring setup. To complete the setup Custom housings are available through veilside180sx on NissanRoadRacing.com. This setup has proven to work exceptionally well, and piecing it together yourself means that it can be fine tuned for your specific setup.

Brakes:

Again, not necessary for the swap, but it’s always advisable to balance out improved acceleration with improved deceleration. The stopping power of well maintained factory brakes is fairly good, however their small size means that they become heat-soaked easily at which point stopping power becomes diminished. There are numerous direct-replacement aftermarket options from name brands such as Wilwood, StopTech, and Brembo. For the more budget conscience there are several conversion brackets available that will allow you to run OEM brakes from everything from a Subaru STi to a 350Z to a Corvette. The easiest and cheapest upgrade option however are simply swapping brakes from a Z32 chassis 300ZX or nearly any other 90s era Nissan with bigger brakes (Q45, Skyline, Silvia, 180SX, etc.) Most of these swap right on without modification and can improve breaking performance greatly and for cheap money too.

A good guide on how to swap the more popular Nissan brake option can be found here: The Definitive 300ZX Brake Swap Page

Chassis Preparation:

This section covers what parts of your car you wont need and can get rid of, and what parts you need to take off and set aside. This is assuming your car is currently unmodified, and you would like to retain all of the existing functions you had before the swap. Obviously if you’ve got some aftermarket parts that might be beneficial to the swap, or if you’re removing features (ie: getting rid of ABS), then you should read ahead to the section that covers that particular part and use your best judgment before selling or scrapping it.

In addition to what is listed here, you may need to take apart some of the interior paneling and equipment to get to things, or simply to make your life easier.

Parts you should Remove and set aside (DO NOT THROW AWAY):

- ABS Actuator, bracket and hardware (if equipped with ABS)

- Accelerator Pedal (only if swapping to a Drive By Wire Throttle) and Throttle Cable

- Air Conditioning Condenser

- Air Conditioning Fan (if equipped)

- Air Conditioning lines

- Battery

- Battery Clamp

- Brake Booster Vacuum Hose and Valve (from booster to firewall tube)

- Clutch Master

- Coolant Temp Sensor (just the single prong one)

- Drive Shaft Safety Brace

- Engine Bay Splash Shield

- Exhaust Hangers

- Front Sway Bar and hardware

- Heater Hose Valve

- Heater Hoses and clamps

- Interior Shifter Trim and Boot

- Lower Engine Harness

- Main Engine Harness

- Passenger’s side front hard brake line from ABS Module to strut tower (if equipped with ABS)

- Power Steering Lines

- Power Steering Reservoir and bracket

- Radiator Clamps and radiator mount hardware

- Rear hard brake line from ABS Module to Frame Rail (if equipped with ABS)

- Rubber shift boot, ring, and hardware

Parts you should Remove and will not need anymore:

- Engine and Transmission (duh)

- Automatic Transmission Control Module

- Automatic Transmission Resistor (label or remove the connector too)

- clutch lines

- complete exhaust (except hangers)

- Cruise Control Actuator

- Cruise Control Module

- Cruise Control Vacuum Pump

- Drive Shaft

- ECM (Engine Control Module) and bracket

- Engine Mounts

- EVAP equipment from the hard line at the firewall forward

- Firewall Brake Booster hard line and bracket

- Firewall Damper

- Firewall Exhaust Heat Shield

- Fuel equipment from the hard lines at the firewall forward

- Ignition lock cable (automatic only)

- Intake

- Power Steering Sensor (label or remove the connector too)

- Radiator and shroud

- Transmission cross member

Take-Away:

Hopefully after reading this you should have a clear idea of what you can expect to get out of this swap, and what kinds of things you will have to do to the car to make it work for you. And if you were considering this swap, hopefully this information has given you a clear enough vision to make an informed decision one way or another.

In Part 2 I will dig more into the nuts and bolts of making the swap work mechanically from mounts to plumbing. [coming soon]

In Part 3 I will cover the electrical and tuning aspects necessary to get your LS1 fully integrated with your chassis. [coming soon]

| Accellerator Pedal (only for Drive by Wire cars) |

| Accellerator Pedal Sub-Harness (only for Drive by Wire cars) |

| Air Conditioning Belt Tension Pulley |

| Air Conditioning Compressor and mount |

| Air Conditioning Lines |

| Air Conditioning Pressure Sensor |

| Air Conditioning Sub-Harness or connectors |

| Alternator and mount |

| Alternator Sub-Harness or Connectors |

| CAS (Crank Angle Sensor) |

| Clutch and Pressure Plate (manual only, duh) |

| Coil Packs (8 of them monted on metal frame with their own sub-harnes) |

| Coolant Temp Sensor |

| CPS (Cams Position Sensor) |

| Decorative Valve Covers |

| Dip-Stick and Dip-Stick Tube |

| Drive Belt Tension Pulley |

| EGR (Exhaust Gas Recirculation) Valve (only certain models have this) |

| Engine Lift Brackets (only certain models have this) |

| Exhaust Manifolds with heat Shields |

| Flywheel (different for auto or manual) |

| Flywheel Dust Covers |

| Fuel Rail |

| IAT (Intake Air Temp) Sensor (only certain models have this) |

| Injectors |

| Intake Plenum |

| Knock Sensors |

| MAF (Mas Air Flow) Sensor |

| MAP (Mass Air Pressure) Sensor |

| O2 sensors (there are 4 of them) |

| Oil Fill Neck |

| Oil Pressure Sensor |

| PCM (Power Train control Module) |

| PCV lines |

| Power Steering Pump, resovoir, and mount |

| Spark Plugs and wires |

| Starter Motor |

| TAC (Throttle Actuator Control) Module (only certain models have this) |

| Throttle body |

| Throwout Bearing (manual only) |

| Uncut Wiring Harness |

| Water Pump |